E-CAT CNC

Overview

E-CAT CNC is a standards-based industrial CNC and automation software solution for Industry 4.0. A truly open machine automation software solution should be able to run on any industrial PC whose hardware is architected for industrial automation, with minimal system management interrupts.

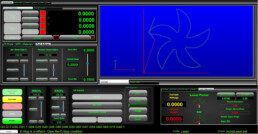

E-CAT CNC is a complete bundle of software that includes a real time operating system, full motion control, PLC, and CNC Control. We have complete solutions for Mill, Lathe, Router, 3D Printer, Plasma, Laser, and combination machines with multiple machine types on the same frame. Yes, we can build custom machine controls.

Benefits

- Compatibility: E-CAT CNC is PC-based software and with the EtherCAT plug-in can connect to virtually any EtherCAT enabled peripherals thus allowing users to customize their systems to meet their specific needs.

- Ease of use: E-CAT CNC software is user-friendly and easy to learn,

- Versatility: E-CAT CNC is versatile and can handle a wide range of machining applications, including routing, engraving, milling, and turning. It can also handle multiple axes and has advanced features like G-code optimization and tool path simulation.

- Affordable: E-CAT CNC is an affordable solution compared to other industrial CNC software, making it a cost-effective choice for light industrial applications.

- Support: E-CAT CNC has a dedicated support team that provides technical support and regular updates to the software, ensuring that users have access to the latest features and bug fixes.

Key Features

- Handle all the core motion control and determinism that machine automation demands

- Address the specific integration and communication tasks associated with Industry 4.0

- Build upon and grow with Microsoft’s features, including simple peripheral connectivity

- Data tracking, reporting, and actionable response from local or cloud-based sources.

- Scale and support other 3rd party software or devices that other software-based machine control technologies can’t